Rethink Seedbed Productivity

The Tiger-Mate 255 field cultivator creates a high-efficiency seedbed for the most accurate seed placement. From crop residue management to soil tilth to seedbed conditions, we designed this field cultivator with an eye on improving your agronomic performance.

Frame Design

Rugged and Reliable From End to end

-

Frame Construction

-

Wheels & Tires

-

Hitch

Higher Productivity

- Greaseless bearings displace 20-40 grease points, depending on model

- Time saved by greaseless bearings equates to up to 40 acres of productivity

Increased Efficiency

- Wings fold together quickly, getting you in and out of the field faster

- 25-inch underframe clearance keeps the residue flowing at higher speed

Versatility

- Exclusive, welding bridge frame stands up to variable conditions under higher field speeds

- Frame designed to flex through difficult soil condistions

Built-in Longevity

- Durable construction and welded cylinders results in greater reliability

- Folding wings distribute load for longer frame life

Durability

- Radial stubble-resistant tires are standard on the Tiger-Mate 255

- Extra durability pays off in the field and during transport

Increased Footprint

- Radial tires have up to a 70 percent increase in footprint, over bias ply tires

- Improves floatation and reduces compaction

A Smooth Ride

- Walking tandems and gauge wheels on the main frame and wings

- Enhances stability and reduces compaction, wing bounce and nosing

Extra Stabilty

- Radial Stabilizer wheels on every wing section provide additional stability and levelness over obstacles

- Optional pivoting stabilizer wheel on wing sections for contour farming

Floating Hitch

- Allows the Tiger-Mate 255 to operate independently of the tractor

- Enhances ground following for consistent depth across terrain

- Available on double-fold models

T-Bone Hitch

- Provides a tighter turn radius

- Standard on all models

Rear Hitch

- Accomodates additional towed conditioning system

- Minimizes passes in seedbed preparation

- Available on all models

Choose Your Hookup

Leveling & Depth Control

Fine-Tune Your Unit For Any Field

Quick and Easy Depth Control

No-Tool Machine Leveling

Sweeps That Will Keep You Up and Running Acre After Acre

Built with Case IH Agronomic Design principles, the Tiger-Mate 255 features our exclusive split-the-middle sweep pattern and proven sweep designs. The results? Better soil tilth, healthy root development, and optimal soil and residue incorporation.

Split-the-Middle Sweep Design

- With a 5-bar frame, the first three shank rows take full cuts through the soil, while the two rear shank rows take smaller cuts to remove the middle.

- Features 26-inch side-by-side shank clearance for improved residue flow

- With the 6.5-inch shank spacing, this sweep pattern ensures 100 percent sweep coverage.

.jpg?width=410&height=265)

Durable, Long-Lasting Sweeps

- Made from high-strength Earth Metal® alloy steel composition

- Unique rear-flowing parabolic design creates superior soil and residue flow

- Longer wear life allows for less-frequent replacement and maintenance.

- Hard and durable without brittleness to stand up to the toughest conditions

- Sharp, forged cutting-edge maintains its edge throughout its life span.

Sweep Options

- Maxxi-Point™ provides better scouring in wet conditions forged cutting edges for reduced draft load; and improved penetration from the extended nose and ½ inch wear point.

- Maxxi-Grip™ has a lower-angle pitch, 1-inch wear tip, two-part knock-on design that mounts to a heavy-duty adapter for easy installation and added strenth

- Maxxi-Point Plus™ has the same design as the Maxxi-Point™ but with a two-part design and mounts to a heavy duty adapter for easy installation and added strength.

Balance Force and Flexibility For a High-Efficiency Seedbed

The workhorse component of the Tiger-Mate 255 field cultivator is the superior shank assembly, combining force and flexibility to support field speeds of up to 10 mph. Thicker shanks, a beefed-up shank guard channel and increased holding power help you manage fast-changing springtime field conditions.

-

Better Soil and Residue Management

- Swept back, high-concavity shank design helps soil ramp up and explode higher to effectively mix particles, break down tough clods and level the soil.

- Thicker, stronger shanks — 11/16-inch compared with the previous 5/8-inch — match to spring pressure for ideal performance.

- Greater residue throughput thanks to 6.5-inch shank spacing that ensures better soil mixing and improved residue distribution.

-

Increased Spring Force

- Greater spring force delivers a 20% increase in holding power, allowing the field cultivator to penetrate hard soils, even at higher speeds.

- Proportional increase in spring force and shank thickness keeps sweeps parallel to the ground for a consistently flat subsurface floor, more accurate seed placement and uniform seedling emergence.

-

Enhanced Durability

- Shank guard channel ensures stability through turns and provides even loading and added durability.

- A 5/8-inch main shank pivot bolt holds tight to stabilize spring pressure and improves the durability of the dual bushing pivot point.

- Low-maintenance features include clamp-style shank mounts, single-bolt installation, welded cylinder and greaseless bearings.

Finishing Tools

Achieve the Perfect Finish

4-bar Tiger-Tine Harrow

- Three tine angle position adjustments for flexible soil finish.

- Indexed tines improve soil leveling.

- Parallel linkage and nonlinked tine bars eliminate depth and level setting.

2-bar Tiger-Tine ACS Harrow With ACS Roundbar Crumbler

- Provides clod sizing and seedbed forming.

- Indexed tines improve soil leveling.

- Parallel linkage and non-linked tine bars eliminate depth and level setting.

- Ideal for mellow or sandy loam soils found in prairie type soils.

3-bar Extreme Tiger-Tine ACS Harrow With Spring Down Pressure

- With three bars and twice as many tines, this option improves clod sizing and soil leveling, even on tough soils.

- Extreme Tiger-Tines are redesigned for maximum flexibility, allowing residue to filter through the tines.

- Four precise tine angle settings, convenient handle and quick pin allow tines to be adjusted to the soil.

- Large 14-inch TigerPaw™ Crumbler rolling reels pulverize the soil for a smooth seedbed surface

3-bar Extreme Tiger-Tine ACS Harrow With Hydraulic Down Pressure

- This option, paired with the TigerPaw Crumbler, has all the advantages of the 3-bar Extreme Tiger-Tine ACS harrow, but with hydraulic down pressure.

- The Crumbler may be placed in float or lifted on the go to avoid wet spots.

- The hydraulic down pressure system offers independent adjustment of each section to easily match downforce with field conditions.

- This harrow is ideal for soils with heavy residue and tough clods.

3-bar Spike-tooth ACS Harrow With Spring Down Pressure

- Paired with the Case IH TigerPaw Crumbler, this high-iron harrow aggressively breaks up clods, evenly distributes crop residue and levels the soil for a smooth finish.

- The larger formed bar on the Crumbler adds clod-busting power and excellent durability.

- Best choice for tough clods in forest soils prone to cloudiness.

3-bar Spike-tooth ACS Harrow With Hydraulic Down Pressure

- Paired with the Case IH TigerPaw Crumbler, this hydraulic down pressure system offers independent adjustment of each section to easily match downforce with field conditions.

- The durable Crumbler busts tough clods with ease.

- The Crumbler may be placed in float or lifted on the go to avoid wet spots.

- This harrow option provides even crop residue distribution and excellent soil leveling.

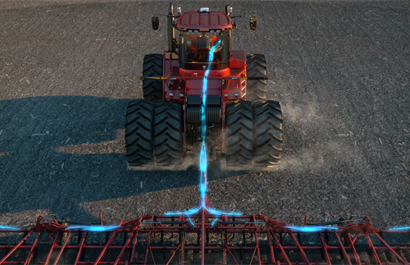

AFS Technology

Monitor Agronomic Quality With AFS Soil Command

Proven and dependable AFS components integrated into the Tiger-Mate 255 field cultivator match the performance and ruggedness of Case IH tillage tools for increased durability, and in-cab controls for each system component allow operators to make every inch of the field an ideal crop environment.

Coordinated Control

Operator Efficiency