Results

- Ag Equipment

- Construction Equipment

- Precision Farming

DJI Agras T50 Drone

Learn more about this product!

- Parts

2026 Oil & Filter Sale

Deals on Oil, Coolant and Much More..

- Service

- Customer Resources

- About Us

- Community

- Family of Companies

-

Login or Register

Register an account with RME to store your favorite equipment and easily compare between units.

Register

- Ag Equipment

- Construction Equipment

- Precision Farming

DJI Agras T50 Drone

Learn more about this product!

- Parts

2026 Oil & Filter Sale

Deals on Oil, Coolant and Much More..

- Service

- Customer Resources

- About Us

- Community

- Family of Companies

- Home

- NEW AGRICULTURE EQUIPMENT

- Case IH

- Planting & Seeding

- 2000 Series Early Riser®...

2000 Series Early Riser® Planters

There’s a Farmall to meet your operation’s demands. From the value-packed utility Farmall A and 100A series,to the deluxe utility Farmall C Series or the compact C series, the premium utility Farmall U series and the specialty, narrow-footprint, Farmall N and Farmall V series.

Interested in this 2000 Series Early Riser® Planter unit but need some financing? Message us TODAY to speak with one of our financing specialists.

The Latest in High-Efficiency Planting

Early-Riser Large Front-fold Planter

- Expanding the lineup of 2160 Early Riser large front-fold planters with two new 60-foot configurations — the new 24-row 30-inch and 47-row 15-inch with split

- New configurations include a 24-row unit with 30-inch spacing for planting corn or soybeans, and a split-row unit that can plant 15-inch rows of soybeans or specialty crops and 30-inch rows of corn/li>

- 60-foot toolbar gives producers the efficient productivity they need to hit optimal planting windows

Built for Accuracy at Your Speed

Recent field testing shows our industry-leading new Early Riser planter row unit is where speed, precision and performance meet. The unit is high-speed capable while delivering accurate seed placement, net effective stand and harvest data.

Watch this video to learn how the Early Rise row unit is designed for superior agronomic performance.

-

Vertical Row Unit Travel

Sixteen inches of vertical row unit travel improves performance in varied terrain while providing greater clearance for residue managers. Cast-iron row unit is built with larger, common hardware and fewer parts.

-

Opening System

Larger diameter and thicker Earth Metal® offset opener blades are agronomically designed to slice through residue and tough soil conditions.

-

Furrow Management System

Pulled gauge wheels with soil relief grooves eliminate sidewall compaction and control soil flow through changing ground speeds. The furrow forming point creates the industry’s only flat-bottom seed trench.

-

Downforce Management

Through up-or-down hydraulic pressure, automatic and row-by-row DeltaForce® achieves consistent weight on the gauge wheels for unparalleled depth control. Or select air downforce with or without in-cab gauge wheel feedback.

-

Floating Residue Management System

CleanSweep® air cylinders allow for in-cab adjustments of residue manager ride to accommodate soil and residue conditions.

-

Two-stage Closing System

Inverted closing disks zip the trench closed, placing high-moisture soil directly onto the seed. The press wheel ensures proper seed-to-soil contact.

Seed Delivery

Precise Per-Row Seed Metering

To achieve the perfect picket fence stand, you need a seed meter capable of delivering accurate and consistent seed singulation, populations and in-row spacing. The all-new seed meter and electric drive at the heart of the new 2000 series Early Riser planter row unit do just that. And it does it at your speed.

Get an inside look at how Advanced Seed Delivery™ provides the most precise control from the meter to the furrow.

-

vSet® 2 Seed Meter with vDrive® Electric Drive Motor

Row-by-row overlap control and curve compensated spacing deliver optimal seed singulation and spacing. A simple design provides tool-free crop changes and reduces mechanical drive components. -

Advanced Seed Delivery (ASD)

For the most accurate seed delivery and placement to and in the trench, the 2000 series ASD option includes the new SpeedTube from Precision Planting. Available for corn and soybeans, the SpeedTube™ uses a flighted belt to control the delivery of the seed from the meter to the furrow, eliminating the drop and tumble variability of traditional gravity drop tubes, especially at high speeds.

Bulk Fill System

Engineered to Deliver

Our 2000 series Early Riser planters are equipped with bulk-fill tanks to provide reliable seed delivery from the tank to the mini-hopper — no matter the seed population. The 2160, 2150 and 2140 models feature two bulk-fill tanks, and the 2130 model features one 50-bushel tank. Plus, optional 1.9-bushel, on-row individual hoppers are available on all 2130 and 2150.

Carrier System

Reduced Compaction & Better Maneuverability

Extend your planting window with the Rowtrac™ Carrier System, currently available as a factory-installed option. With increased flotation over a wheeled carrier, this carrier system reduces compaction and improves yield potential in wet spring conditions. Plus, it provides better maneuverability with transport steering and excellent ground contact on uneven terrain with fore-aft track oscillation.

Watch this video to discover more unmatched features of the Rowtrac Carrier System.

AFS Technology

Putting Technology to Work for You

Control System Options

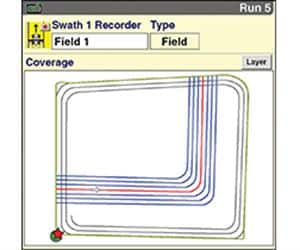

- Make in cab adjustments with the single-screen AFS 700 Pro

- Share planter data with your home computer or trusted 3rd party advisor

- Choose between total planter control and continuous feedback

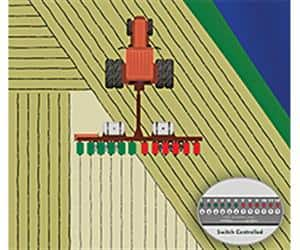

Row by Row Shut-offs

- Eliminates overlap with the all new, maintenance-free v-Drive electric meter drive system

- Uses GPS to provide row unit shutoff capabilities – automatically disengages rows when you overlap areas that have already been planted

- Allows you to adjust your planting rate from the cab using the AFS Pro 700 control center

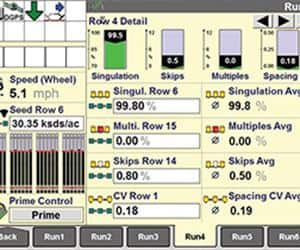

Advanced Seed Information

- Immediate seed placement feedback to make corrections

- Provides immediate seed sensing and pinpoints singulation, skips and multiples

- Compares quality of spacing between populations

- Available for corn, popcorn, sugar beets and sunflower crops

AccuGuide™

- Fully integrated auto-guidance system that works with your Steiger® Magnum™ or Puma® tractor

- Choose your level of accuracy (sub-meter to sub-inch)

- Reduces gaps and overlaps

Precision Planting

Fit the Way You Farm

-

DeltaForce®

- DeltaForce hydraulic down force helps achieve the ultimate row-by-row control across varying soil conditions and speeds

- Automatically provides the required up or down pressure to achieve consistent weight on the gauge wheels, resulting in highly accurate seed depth

- Measures gauge wheel load 200 times per second, triggering hydraulic adjustments to add or remove weight five times every second

-

CleanSweep®

- Floating residue managers with CleanSweep® air cylinders provide flexibility and enhanced performance to clear even the toughest residue — without distributing soil

- Make in-cab ride adjustments from the tractor cab through your AFS Pro 700 monitor

- Simply add down pressure for tougher no-till conditions, or add up pressure for soft and mellow conditions

Maintenance & Uptime

Easy Service Access & Simplified Adjustments

Many components of our 2000 series Early Riser planters – including the metering system and row unit settings – provide tool-free crop changes and adjustments.

Plus, we’ve eliminated all the mechanical components – hex shafts, bearings, couplers, sprockets, chains and clutches – needed to turn a conventional planter. Fewer things to go wrong means reduced, simpler maintenance.

Customization Options

Built to Your Specs

-

Crop Protection

- AMVAC SmartBox® option delivers granular insecticide in-furrow

- Closed on-row system helps minimize exposure to granular insecticides and provides superior crop protection

- Electronically controlled metering for precise application, while adjusting for changes in ground speed

- Available row by row shut-offs help reduce input costs

-

Fertilizer Application Options

- New liquid fertilizer system is designed for accurate application at speeds from 3 to 10 mph

- Centrifugal pump accurately delivers a broad application rate range

- On 2160, 2150 and 2140 planter models, factory-installed seed-fertilizer combination units feature a 400-600 gallon liquid fertilizer capacity plus bulk-fill seed hoppers

- Factory-available fertilizer, including all toolbar and row unit distribution to the furrow, is available for the 2130 planter model; tractor-mounted tanks required

- Available row-by-row shut-offs help reduce input costs

Find Equipment

Connect With Us

Sign up for deals & discounts

Subscribe NowBy signing up, you agree to receive emails. Unsubscribe at any time by clicking on the unsubscribe link at the bottom of our emails. Contact us for questions.