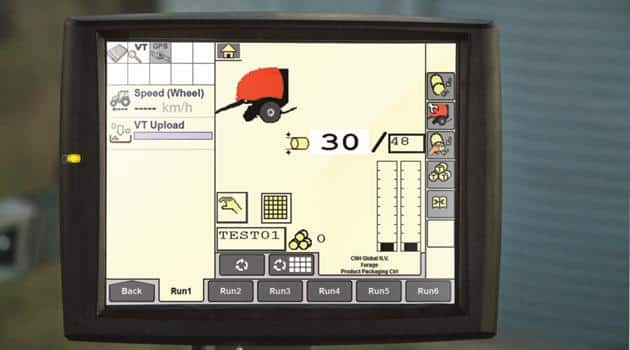

This system controls the tractor stop, bale wrap and bale eject functions without any operator input required. Paired with a Puma® or Maxxum tractor, featuring a CVXDrive™ continuously variable, PowerDrive powershift or ActiveDrive 8 dual-clutch transmission, operators can take advantage of ISOBUS Class 3 controls to automatically stop the tractor when the target bale size is reached. After that, net wrap is automatically applied and, when the wrap cycle is complete, the baler tailgate raises and lowers automatically to eject each wrapped bale. Once the completed bale is ejected, the operator can simply move the tractor shuttle lever to the forward position and go.